Calibrating a laboratory pycnometer is an essential procedure in any laboratory where density measurements must meet high standards of accuracy and reproducibility. Although pycnometers are manufactured as calibrated volumetric instruments, their effective internal volume may change slightly over time due to repeated use, thermal stress, residue buildup or operation at temperatures different from the original calibration conditions. For this reason, periodic calibration is necessary to ensure reliable analytical results.

In chemical, pharmaceutical, industrial and quality control laboratories, density is a critical physical property used to characterize substances, verify purity and comply with regulatory specifications. Even a small error in the volume of a pycnometer can lead to significant deviations in calculated density values, potentially affecting data interpretation and decision-making. Proper calibration minimizes these risks and ensures traceability of the measurement.

What Pycnometer Calibration Means

Calibrating a pycnometer involves determining its true internal volume at a specified reference temperature, most commonly 20 °C or 25 °C. The real volume may differ slightly from the nominal value provided by the manufacturer, especially after prolonged use or repeated thermal cycling.

Calibration does not modify the instrument itself; instead, it establishes the actual volume to be used in density calculations. This practice is particularly important in quantitative analysis, method validation and regulated laboratory environments.

In most cases, calibration is performed using a reference liquid with a well-known density, typically distilled or deionized water, whose density values at specific temperatures are accurately documented in standard reference tables.

Principle of Pycnometer Calibration

The calibration principle is based on the relationship between mass, volume and density. Since the density of water at a known temperature is a constant reference value, the true volume of the pycnometer can be calculated from the measured mass of water it contains.

The fundamental equation is:

volume = mass / density

By accurately weighing the pycnometer filled with water and knowing the density of water at the calibration temperature, the real internal volume of the instrument can be determined. This volume should then be used in all subsequent density measurements performed with that pycnometer.

Materials Required for Pycnometer Calibration

To achieve accurate and reproducible calibration results, the following materials and equipment are required:

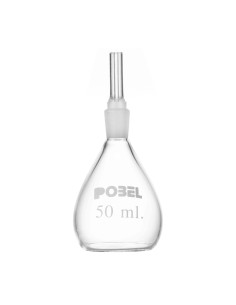

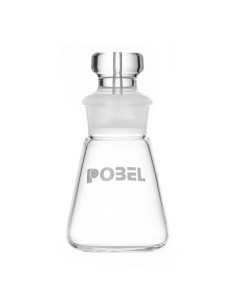

- Clean and dry pycnometer

- High-precision analytical balance

- Distilled or deionized water

- Thermostatic bath for temperature control

- Calibrated laboratory thermometer

- Lint-free absorbent paper

- Support stands and clamps

- Watch glass

- Density tables for water at various temperatures

Temperature control is especially critical, as water density changes with even small temperature variations. Calibration should always be performed under stable and controlled conditions.

Step-by-Step Pycnometer Calibration Procedure

Cleaning and Preparation

Before calibration, the pycnometer must be thoroughly cleaned to remove any residues or contaminants. It should be washed with a neutral detergent, rinsed several times with distilled water and dried completely. Any remaining moisture or contamination can affect the mass measurement and introduce errors.

Determining the Mass of the Empty Pycnometer

Once clean and dry, the pycnometer is weighed using an analytical balance to determine its empty mass. The instrument should be allowed to equilibrate to room temperature, and direct handling should be avoided to prevent heat transfer from the hands.

Filling with Reference Water

The pycnometer is filled with distilled or deionized water at the calibration temperature. The stopper is inserted, allowing excess water to escape through the capillary. It is essential to ensure that no air bubbles remain trapped inside the pycnometer.

Thermal Stabilization

The filled pycnometer is placed in a thermostatic bath until thermal equilibrium is reached. This step ensures that the water density corresponds exactly to the reference value used for calculations.

Determining the Mass of the Filled Pycnometer

After thermal stabilization, the exterior of the pycnometer is carefully dried without warming it. The pycnometer is then weighed again. The difference between the filled and empty masses corresponds to the mass of water contained in the calibrated volume.

Calculating the True Volume

Using the density of water at the calibration temperature, the true internal volume of the pycnometer is calculated. This value should be recorded and used for all future density determinations.

Calibration Frequency

The frequency of pycnometer calibration depends on laboratory requirements and usage conditions. General recommendations include:

• Calibration before first use

• Periodic recalibration in quality control laboratories

• Calibration after exposure to extreme temperature changes

• Verification after mechanical shock or damage

• Recalibration when high analytical accuracy is required

In regulated environments, calibration is typically included in standard operating procedures.

Why Pycnometer Calibration Is Important

Accuracy of Density Measurements

The primary reason for calibrating a pycnometer is to ensure accurate density measurements. Small volume errors can result in significant density deviations, particularly when comparing closely related samples.

Reproducibility of Results

Calibration ensures that measurements performed at different times are comparable. This is critical for stability studies, quality control programs and method validation.

Regulatory Compliance

Many analytical standards and quality systems require periodic verification and calibration of volumetric instruments. Proper calibration supports compliance with ISO, GLP and GMP requirements.

Metrological Traceability

Calibrating the pycnometer using a reference liquid with known density provides traceability to recognized measurement standards, enhancing confidence in analytical results.

Common Errors During Calibration

Several common mistakes can compromise calibration accuracy:

- Inadequate temperature control

- Use of impure or contaminated water

- Failure to remove air bubbles

- Improper drying of the pycnometer exterior

- Handling the pycnometer during weighing

- Using incorrect water density tables

Avoiding these errors is essential for obtaining reliable calibration data.

Applications of a Calibrated Pycnometer

A properly calibrated pycnometer is used in:

- Liquid purity analysis

- Industrial quality control

- Chemical formulation studies

- Density determination of powdered solids

- Academic research

- Comparison of raw materials and finished products

In all these applications, calibration is the foundation for accurate and reproducible density measurements.

Conclusion

Calibrating a pycnometer is a fundamental practice for ensuring the accuracy and reliability of density measurements in laboratory environments. Although the procedure itself is relatively straightforward, it requires careful attention to temperature control, cleanliness and proper weighing techniques. A well-calibrated pycnometer improves analytical precision, supports regulatory compliance and provides traceable, reproducible results. For any laboratory relying on density measurements, regular pycnometer calibration should be considered a standard and essential practice.