MEASUREMENT AND APPARATUS

Laboratory measuring instruments

When you step into a research environment, you realize that science is not only intuition, but also the remarkable ability to quantify the world. laboratory measuring instruments are the foundation on which any discovery is built, allowing abstract variables such as volume, density, or temperature to be converted into accurate data.

The importance of precision in scientific instruments

Accuracy in results is not a luxury—it is a technical requirement for reproducibility. If a measurement fails, the entire subsequent process collapses like a house of cards. That is why volumetric glassware plays a leading role in day-to-day work.

When we talk about quantifying substances, we mean items designed to minimize human error. Class A pipettes, for example, undergo rigorous calibration processes to ensure the delivered volume is exactly what the scale indicates. This reliability is what allows complex processes—such as chemical synthesis or food quality control—to maintain consistent standards of excellence over time.

Classification of volumetric quantification systems

To understand how work is organized on a lab bench, it is useful to divide the tools according to their specific function. Not all processes require the same error tolerance:

-

Controlled dispensing systems: where burettes with reservoirs are essential for chemical titrations, allowing reagents to be added drop by drop with full control of the flow.

-

Exact containment vessels: such as volumetric flasks, designed to contain a specific volume at a given temperature—essential for preparing standard solutions.

-

Transfer instruments: where single-channel micropipettes allow extremely small volumes (in the microliter range) to be handled with repeatability that manual glassware cannot always achieve.

Technology applied to liquid handling

The evolution of laboratory measuring instruments has made it possible to move from purely manual methods to semi-automatic systems that protect the technician’s health. Handling corrosive or toxic substances requires maximizing the distance between the operator and the liquid.

Using an automatic pipette controller not only speeds up long series of work, but also eliminates obsolete and dangerous techniques. In addition, integrating dispensers directly onto reagent bottles ensures a constant extracted amount, reducing material waste and improving the cost center’s operational efficiency.

Equipment for specific physical and chemical analysis

Beyond volume, other properties define the quality of a sample. Devices intended for measurement and supporting apparatus are varied:

Densimetry and fluid control

In sectors such as petrochemicals or wine production, determining density is crucial. Here, glass cylinders act as the ideal support vessel for clear, stable readings. Borosilicate glass ensures there are no chemical interactions that could alter the result, keeping the sample’s purity intact throughout observation.

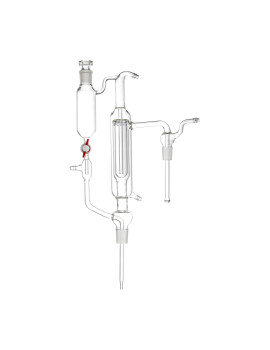

Temperature control and distillation

In purification processes—such as those carried out with automatic distillers—continuous measurement of boiling and condensation temperature is what guarantees distillate purity. A difference of just a few degrees can mean unwanted impurities in the final product, which can invalidate a production batch.

Ergonomics and precision in modern pipetting

Researcher well-being is a factor that is often overlooked, yet it directly affects data quality. Variable-volume micropipettes have been designed with an ergonomic approach to reduce thumb and wrist fatigue. A tired hand is more likely to make aspiration errors, so good design is, in itself, a precision tool.

In addition, for laboratories with high workloads, multichannel micropipettes make it possible to process entire plates of samples simultaneously. This not only saves time, but also ensures all samples are treated under the same timing conditions—critical in enzymatic or immunological assays.

Need technical advice on precision equipment?

We know that choosing the right instrument can be complex given the variety of regulations and accuracy classes available. At Pobel, we have spent decades manufacturing and distributing solutions that adapt to the real needs of every researcher—from traditional glassware to the most advanced digital systems. If you want to optimize your analytical processes or renew your inventory with guaranteed durability, our team is ready to listen.

Contact us to receive personalized information and find the equipment that best fits your projects.