Fractional distillation is a key method in chemical engineering, laboratory science and industrial refining. It is used to separate mixtures of miscible liquids with relatively close boiling points. Unlike simple distillation, this technique incorporates a fractionating column that provides multiple vapor-liquid equilibrium stages. These repeated cycles significantly increase separation efficiency, resulting in high-purity fractions.

Fractional distillation plays a central role in solvent purification, petrochemical production, analytical chemistry and the preparation of high-purity reagents. Its efficiency stems from its ability to exploit the slight differences in volatility among the components of a mixture.

Principle of Operation

The principle behind fractional distillation lies in repeated condensation and vaporization cycles. As the liquid mixture is heated, vapors rise through the fractionating column. Inside the column, the vapor encounters cooler surfaces or packing materials, causing partial condensation. The condensed liquid, enriched in less volatile components, flows back downward, while more volatile components continue ascending.

Each equilibrium cycle acts as a theoretical plate, improving separation. Columns with structured packing, glass beads, metal saddles or perforated plates increase surface area and therefore the number of effective separation stages.

Once the vapor reaches the top of the column, it passes through a condenser, where it is cooled back to the liquid state and collected as the distillate.

Materials and Equipment Used in Fractional Distillation

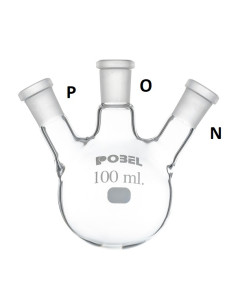

A complete fractional distillation setup typically includes:

-

Condenser (Liebig, Allihn, or coil condenser)

-

Thermometer and adapter

-

Receiving flask

-

Ground-glass joints and connectors

-

Heating mantle or hot plate

-

Support stands, clamps and safety accessories

-

Vacuum adapters (when reduced pressure is used)

These components must withstand heat, provide stability and ensure leak-free connections.

Applications

Fractional distillation is used across many fields:

-

Separation of solvent mixtures

-

Purification of liquid reagents

-

Determination of volatile components in analytical chemistry

-

Refining petroleum derivatives

-

Production of alcohols, hydrocarbons and specialized organic compounds

-

Recovery of reusable solvents

-

Preparation of standard mixtures

It is also widely used in environmental testing, food chemistry, pharmaceutical development and synthetic organic chemistry.

Types of Fractional Distillation

1. Laboratory Fractional Distillation

Common in universities and research labs, this method uses glass columns packed with various materials. It enables separation of alcohols, ketones, esters and other organic mixtures with close boiling points.

2. Industrial Fractional Distillation

Large towers, sometimes more than 50 meters tall, are used in petrochemical refineries. They contain trays or packing that maximize contact between rising vapors and descending liquids, producing distinct fractions extracted at various levels.

3. Vacuum Fractional Distillation

By lowering the pressure inside the system, boiling points decrease. This protects thermally sensitive compounds from decomposition.

4. Steam-Assisted Fractional Distillation

Steam is introduced to help volatilize substances with high boiling points. This is especially useful for essential oils and aromatic compounds.

5. Reactive Distillation

Reaction and separation take place simultaneously inside the same column. This enhances conversion efficiency and reduces downstream processing.

Advantages

-

High separation efficiency

-

Production of highly pure fractions

-

Adaptable to small-scale and industrial applications

-

Effective with mixtures containing components with close boiling points

-

Stable and controllable through temperature monitoring

Limitations

-

Requires specialized and sometimes expensive equipment

-

Higher energy consumption

-

Sensitive to variations in pressure and temperature

-

May require long columns for difficult separations

Conclusion

Fractional distillation remains one of the most powerful separation techniques in chemistry and industry. Its ability to provide highly purified components makes it indispensable in analytical research, chemical synthesis, petrochemical processing and manufacturing. Using proper materials such as high-quality fractionating columns, condensers and ground-glass joints ensures reproducible, efficient and safe operation.