Ground glass joints are essential components used in laboratory glassware to provide tight, hermetic, and interchangeable connections between flasks, condensers, funnels, adapters, and other equipment. Their correct measurement is crucial to ensure compatibility and avoid leaks, instability, and malfunction during chemical reactions, distillations, extractions, or processes involving vacuum or pressurized systems. Understanding how male and female joints are measured allows technicians and researchers to work safely and efficiently with scientific glassware.

Concept of Ground Glass Joints

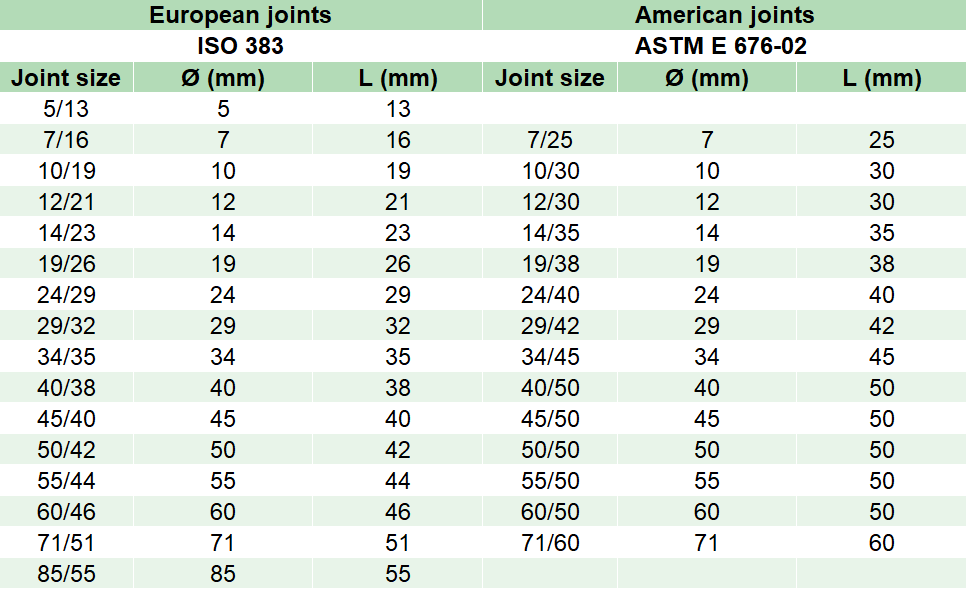

Ground glass joints follow a standardized numerical designation system expressed as a fraction, such as 24/29 or 19/26. The first number refers to the diameter at the widest end of the joint, while the second number indicates the length of the ground section. This system ensures compatibility between male and female joints as long as the first number is identical on both parts.

Difference Between Male and Female Joints

Male and female joints differ in structure:

- The male joint is the part that fits into another.

- The female joint is the part that receives the male.

Both components must share the same upper diameter value to ensure compatibility. If the first number differs, the pieces will not fit properly, even if the lengths appear similar.

How to Measure Ground Glass Joints

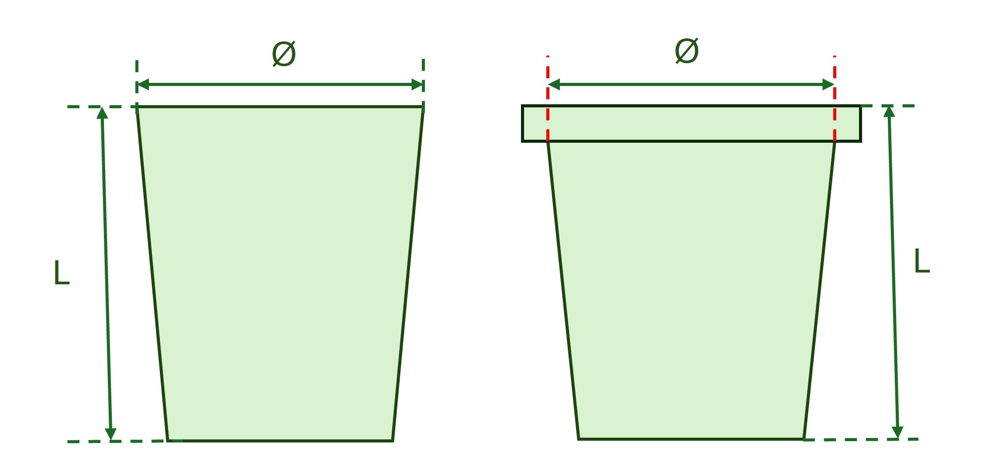

1. Measuring the Outer Diameter

The outer diameter at the widest part of the joint is the most important measurement. Using a caliper, the value should be taken at the upper edge of the ground zone. This measurement, expressed in millimeters, corresponds to the first number in the joint notation.

2. Measuring the Length of the Ground Zone

The second value in the joint notation corresponds to the length of the ground area. Using a caliper, this distance is measured from the upper edge of the ground section to its lower end.

3. Compatibility of European and American Joints

Although European and American systems may differ slightly in cone angle or tolerances, compatibility is generally maintained if the upper diameter value matches. Users must always verify the first number before assembling glassware.

The most common sizes used in the laboratory are:

Importance of Accurate Measurement

Incorrect measurement of ground glass joints may lead to:

- Gas or vapor leaks.

- Vacuum loss or pressure imbalance.

- Contamination issues.

- Accidental detachment of glass parts.

- Glass breakage due to improper fit.

The fundamental rule is that the first number must match. If the diameters are equal, the joint is compatible, even if the lengths differ.

Conclusion

Proper measurement of male and female ground glass joints ensures safe, efficient, and hermetic connections in laboratory systems. Knowing how to measure diameter and length, as well as understanding compatibility rules, allows professionals to assemble glass equipment reliably, reducing risks and improving workflow quality.